Do you have a question about this application? Ask our specialists

Contact us

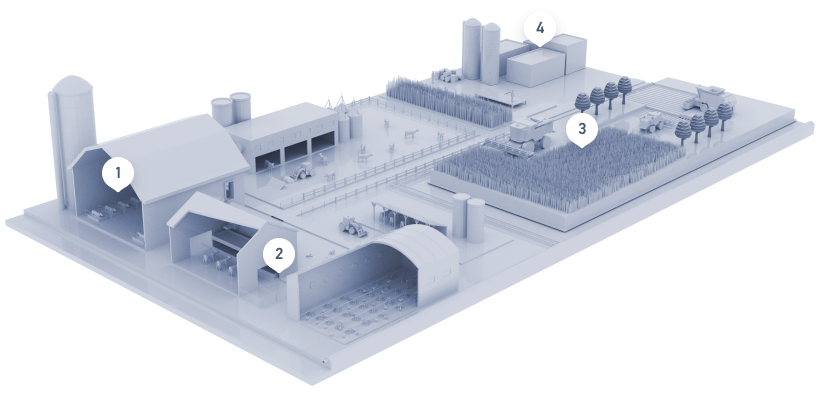

The Sugar Production Process

The process of producing and refining sugar is a multi-step journey that transforms raw sugarcane or sugar beet into the familiar sweet crystals we use in our daily lives. It typically begins with the extraction of sugarcane juice or sugar beet juice, followed by the removal of impurities through a process called clarification. The clarified juice is then evaporated to concentrate the sugar content, and the resulting syrup is crystallized. Further refining steps may include the removal of any remaining impurities, resulting in the production of white sugar. The entire process requires precision, as it involves numerous chemical and mechanical steps to produce high-quality sugar that meets industry standards.

Our Role in Sugar Production

What We Do

Lime plays a pivotal role in sugar production and refining. It is primarily used to adjust the pH levels of sugar juice. By adding lime, the juice becomes less acidic, creating an environment where impurities, such as proteins and colorants, can easily coagulate and be removed. Lime aids in the clarification process, resulting in a cleaner sugar juice. Additionally, it assists in the removal of unwanted colorants, contributing to the production of white, refined sugar. Lime also promotes the precipitation of impurities like calcium carbonate and magnesium hydroxide, which can be efficiently separated from sugar juice. Its antimicrobial properties help prevent microbial growth in the juice, enhancing the overall quality and shelf life of the sugar.

Equipment and corresponding processes may also need updated or replaced over time from evolution of technology or normal wear and tear.

How it Helps

- pH Regulation - Quicklime creates an environment where impurities can be efficiently removed, ensuring a purer and higher-quality sugar product.

- Color Removal - Quicklime is instrumental in the removal of colorants in the sugar juice, contributing to the production of crystal-clear, white sugar.

- Removal of Impurities - Quicklime encourages the precipitation of impurities like calcium carbonate and magnesium hydroxide, which can be easily separated from sugar juice.

Lime Slaking Systems & Upgrades

Carmeuse Systems provides comprehensive equipment and storage solutions. We offer lime slaking systems, soda ash systems, dry material storage, and more. Our experienced engineers can design tailored solutions, including new lime handling systems, slakers, and retrofits or upgrades for existing equipment.

Supplying Lime for Various Applications