Do you have a question about this application? Ask our specialists

Contact us

Types of Flooring that Use Limestone in Production

For manufacturers of building materials, there are many items to consider including the appropriate materials to create a safe, stable, and usable space while also keeping costs low. Specifically, in flooring, lime can be used to offset production costs for manufacturers while improving the safety and quality of the materials. The challenge is finding the right raw materials that meet or exceed these standards while providing a low-cost solution to meet your customers’ expectations. It is important to choose products that minimize this impact.

Carmeuse limestone products are used in the manufacturing of tile and polymer-based (vinyl) flooring and carpet backing. Tile and polymer-based (vinyl) flooring systems require a unique set of mechanical properties such as stiffness, wear resistance, and strength that must stand the test of time while carpeting manufacturers must create a final product that can withstand the rigors of the home and office traffic while meeting specifications.

Our Role in Production of Flooring Materials

What We Do in the Manufacturing of Carpet

Ground calcium carbonate (GCC), referred to as “filler” in the carpet industry, is blended in quantities as high as 35% (by weight) with latex to form the adhesive backing on tufted carpet. This adhesive holds the carpet fibers together while also improving many of the carpet’s properties.

The addition of our GCC “filler” provides a desirable color and naturalness to the carpet backing that is sought after by the consumer. It adds weight and improves the overall durability resulting in a more premium carpet. The addition of the GCC also significantly reduces the amount of costly latex needed, lowering the overall production cost.

What We Do in the Manufacturing of LVT Flooring

Tile and polymer-based (vinyl) flooring systems require a unique set of mechanical properties such as stiffness, wear resistance, and strength that must stand the test of time. Your customers expect an aesthetically pleasing, durable product that meets their budgetary needs.

How it Helps

- Lower Production Costs – By including lime as a ‘filler’ in your processes, manufacturers can increase weight and durability while reducing costs.

- Improved Product Quality – Improved stiffness, hardness, and sound insulation properties to give a more premium feel to the product.

- Increase in Safety - Provides additional flame retardancy to increase safety.

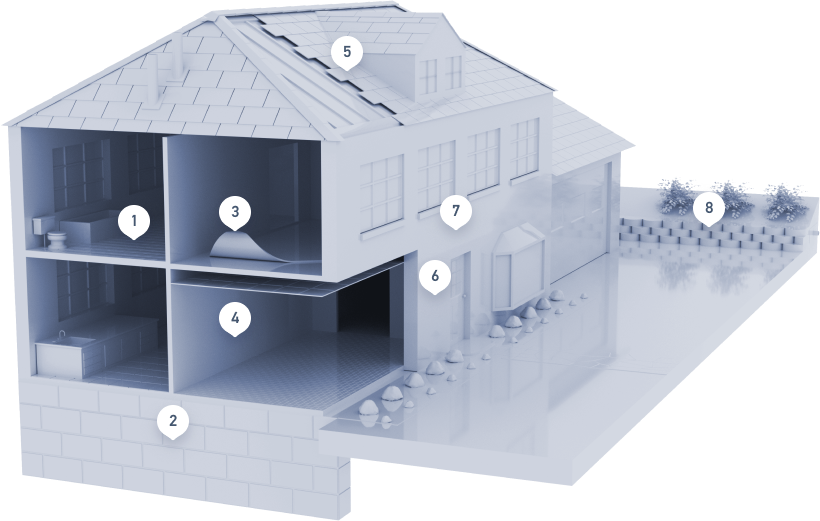

Lime Storage & Conveying Systems

High volume production places high demand on your equipment. Carmeuse Systems provides comprehensive equipment and storage solutions for storage and pneumatic transfer of your dry bulk materials. Our experienced engineers can design tailored solutions, including new lime handling systems and retrofits or upgrades for existing equipment.

Supplying Limestone for Various Applications