Do you have a question about this application? Ask our specialists

Contact us

Mortar & Plaster in Building Processes

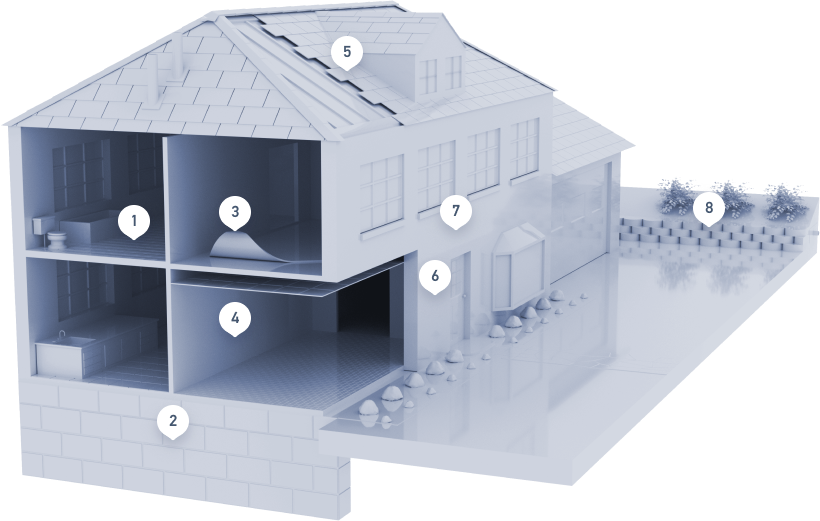

Mortar and plaster are indispensable components in the building process, serving as the binding agents that hold a structure together and provide both functional and aesthetic benefits. Mortar, typically made of a mixture of cement, sand, and water, forms the essential adhesive that secures bricks, stones, and other masonry materials, creating the structural integrity of walls and foundations. Plaster, on the other hand, is used to provide a smooth and protective finish to interior walls and ceilings. Beyond their structural roles, these materials offer insulation, fire resistance, and soundproofing qualities, enhancing the comfort and safety of a building's occupants. Moreover, plaster allows for interior decor and customization, while the strength and durability of mortar are fundamental to a construction's longevity.

Our Role in Production of Mortar & Plaster

What We Do in Mortar & Plaster Manufacturing

Dolomitic hydrated lime plays a crucial role in the formulation of mortars and plasters, offering several advantages in construction applications. This versatile material is often added to mortar and plaster mixes to enhance their workability, durability, and adhesion properties. The presence of dolomitic lime in these building materials acts as a plasticizer, allowing for smoother and more malleable application while also extending the working time, making it easier for masons and plasterers to achieve precise finishes. Additionally, dolomitic lime contributes to improved bond strength, reducing the risk of cracking and ensuring long-lasting, robust structures. Its natural white color can also enhance the brightness and consistency of the finished mortar or plaster, making it an ideal choice for both functional and aesthetic purposes in construction.

Carmeuse produces Type S Lime, or ‘special hydrated lime’ which is a hydrated dolomitic lime used in mortar and plaster under the name “MIRACLE MORTA-LOK®”. By adding dolomitic hydrated lime to mortar and plaster, it allows users to save on material costs without having to sacrifice quality, durability, and efficacy of the product.

How it Helps

- Lower Production Costs – By including lime as a ‘filler’ in your processes, manufacturers can find savings over traditional masonry cement.

- Improved Product Quality – Improves elasticity and durability of the end product while allowing greater efflorescence control.

- Improved Product Functionality – Adds bond strength, improves workability, and enhances waterproofing qualities.

Lime Storage & Conveying Systems

High volume production places high demand on your equipment. Carmeuse Systems provides comprehensive equipment and storage solutions for storage and pneumatic transfer of your bulk materials. Our experienced engineers can design tailored solutions, including new lime handling systems and retrofits or upgrades for existing equipment.

Supplying Lime for Various Applications