Do you have a question about this application? Ask our specialists

Contact us

A Look at the Petrochemical & Oil Gas Industries

The demand for petrochemical products is very widespread, from fuels and plastics to adhesives, resins, textiles, solvents, detergents, paints, coatings, and other consumer goods.

Petrochemical products are derived from crude oil and natural gas. During the drilling process of oil and gas, the resulting drill cuttings pose an environmental hazard because they contain salts and heavy metals. In the oil and gas industry, reliable access to high-quality lime products is essential for operational efficiency and environmentally responsible practices. In addition to helping mitigate hazards from oil sands tailings, lime products also play an important role in oil and petrochemical processing through use in pH adjustment, impurity removal, and environmental remediation.

Our Role in the Oil & Gas Industry

What We Do

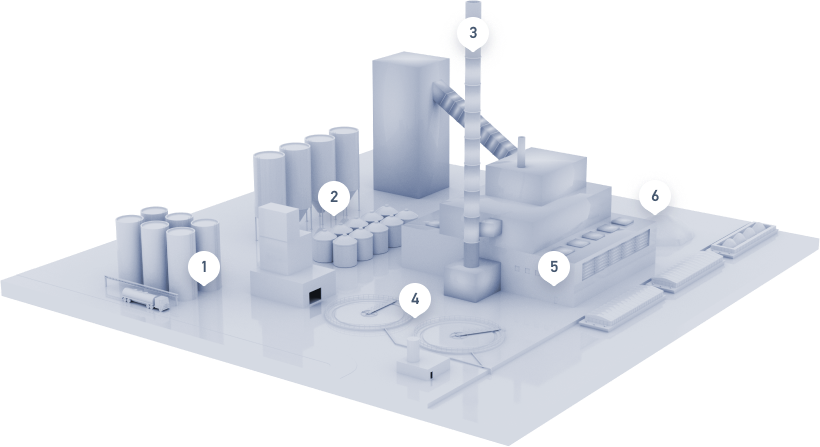

Carmeuse and our affiliates support the needs of petrochemical manufacturers from End-2-End.

Petrochemical plants have manufacturing processes that require drying, pH correction, and acid gas removal to produce new chemical compounds. Our lime-based materials are an ideal alkali choice in the petrochemical and gas industries for cost-effective processing and to meet environmental compliance. Carmeuse lime products, including high calcium quicklime, high calcium hydrated lime and CALSAFE® lime slurry, play an essential role in pH adjustment, impurity removal, and environmental remediation for the oil and gas industry.

By understanding your chemical requirements, Carmeuse can recommend a product to meet the needs of your production process. Carmeuse is also able to provide lime handling equipment, including offloading, pneumatic conveying, and lime slaking systems to help maximize the efficiency of the entire process.

How it Helps

- Consistent Quality – Carmeuse lime and limestone products are routinely tested for quality and consistency, to ensure the right chemistry and physical properties for use in manufacturing processes.

- Use as a Drying Agent – High calcium quicklime can be used as a powerful desiccant for moisture removal.

- pH control – Lime products can be used to adjust the pH and alkalinity of the oil sands tailings and treat impacted soils through environmental remediation.

- Heavy Metal Fixation – Quicklime and hydrated lime can be used to treat mud and drill cuttings to reduce the leaching of salts and heavy metals. Lime products aid in heavy metal fixation by adjusting the pH of the cuttings and reducing metal solubility. This makes the material less hazardous and easier to dispose of.

Lime Slaking Systems & Upgrades

Over time, equipment at petrochemical facilities may need updated or replaced due to normal wear and tear or for the integration of new technologies. Carmeuse supplies advanced equipment solutions for lime storage, handling, and slaking through Carmeuse Systems.

Our expert engineers can design the right solution to keep your production running smoothly, from new lime handling systems and slakers, to retrofits and upgrades for your existing equipment. For additional information related to our lime handling expertise, visit the website.

Supplying Lime for Various Applications