Do you have a question about this application? Ask our specialists

Contact us

The Importance of Flue Gas Treatment in Industrial Applications

To help protect the environment and the air we breathe, flue gases and other industrial emissions require thorough cleaning to reduce the risk of acid gases, heavy metals, and other particulate pollution from being released into the atmosphere. From incinerators and boilers to coal-fueled power plants, flue gases from industrial applications are under strict federal regulation, and companies are responsible for keeping their emissions in compliance. Failure to do so could result in costly fines, but moreover, could lead to devastating impacts on the environment.

Our Role in Flue Gas Treatment

What We Do

Carmeuse and our affiliates support the flue gas treatment needs of industrial facilities from End-2-End.

Carmeuse raw materials play a key role in treating flue gas emissions. Our lime and limestone products enable effective flue gas treatment for industrial applications, by helping to prevent acid gases and heavy metals from being dispersed into the atmosphere.

How it Helps

- Wet Flue Gas Desulphurization – In wet FGD applications, flue gas goes into a scrubber, and a shower of lime slurry rains down counter current to the flue gas flow to remove SO2, HCl & other harmful acid gases. Wet FGD systems have a high efficiency for gas removal and typically use a magnesium-enhanced lime for processing. However, wet FGD systems can also use limestone.

- Dry Flue Gas Desulphurization – An atomized lime slurry is injected into the vessel to react with and remove SO2, HCl & other acid gases. While the lime is introduced as a slurry, all moisture evaporates in the scrubber, leaving a dry product and eliminating the need for wastewater treatment.

- Dry Sorbent Injection (DSI) – In dry sorbent injection, hydrated lime is injected directly into the flue gas duct to remove SO2, HCl & other gaseous pollutants, protecting the atmosphere from harmful emissions. When DSI is used before the air preheater, the injected hydrated lime can decrease corrosion by reducing the risk of the sulfur dioxide (SO2) gas converting to sulfuric acid (H2SO4).

- Ash Stabilization & Solidification – Often, lime products can be used to neutralize and stabilize residual incineration ash. When the material cannot be repurposed, lime can be used to solidify and reduce the leachability of the waste for proper landfill disposal.

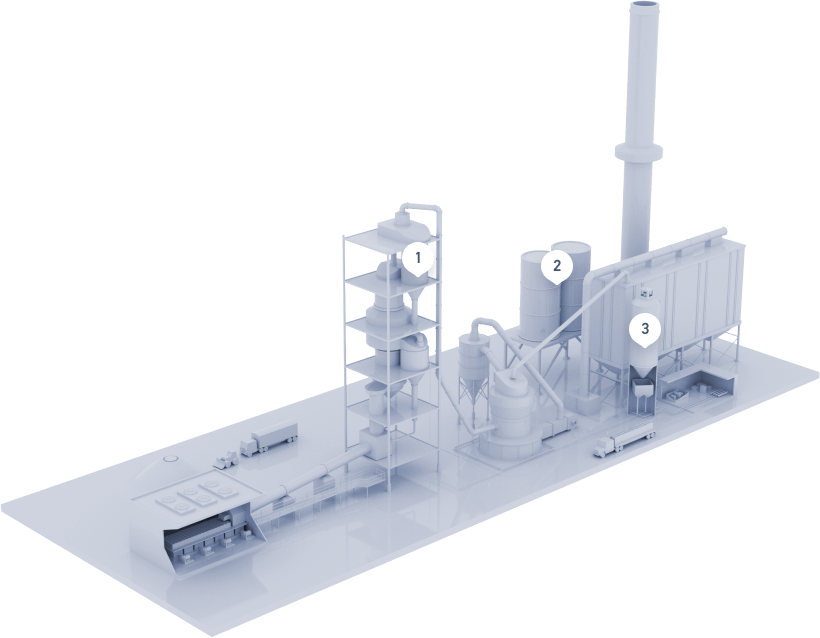

Lime Handling & Slaking Systems

Over time, equipment at industrial facilities may need updated or replaced due to normal wear and tear or for the integration of new technologies. Carmeuse Systems supplies advanced equipment solutions for lime storage, handling, and slaking.

Our expert engineers can design the right solution to keep your flue gas treatment activities running smoothly, from new lime handling systems and slakers, to retrofits and upgrades for your existing lime handling equipment. For additional information related to our systems expertise, visit the website.

Supplying Lime for Various Applications