Do you have a question about this application? Ask our specialists

Contact us

The Importance of Aluminum Production

Aluminum is a cornerstone of modern society, with its applications extending from aerospace and transportation to construction, packaging, and beyond. In the aerospace sector, aluminum's low density and high strength make it indispensable for aircraft components, contributing to fuel efficiency and safety. In the construction industry, aluminum's corrosion resistance and malleability result in durable, low-maintenance structures. Transportation relies on aluminum for its lightweight properties, reducing fuel consumption in vehicles and enhancing the efficiency of trains and ships. Additionally, aluminum's recyclability aligns with sustainability goals, making it a preferred material for eco-conscious packaging and consumer goods. As a conductor of electricity and heat, aluminum plays a significant role in the electrical and electronics industry.

Our Role in Aluminum Production

What We Do

In the extraction process, lime is used to optimize the pH levels of ore processing solutions, creating the ideal conditions for efficient aluminum recovery. By adjusting the pH, lime enhances the dissolution and separation of aluminum from the ore, leading to higher extraction yields and increased purity of the extracted aluminum.

Lime also serves a crucial function in the removal of impurities, particularly silica and iron. It precipitates these impurities, making them insoluble and easy to remove. This process not only enhances the quality and purity of the extracted aluminum but also ensures that the final product meets the stringent requirements of various downstream industries, including aerospace and construction.

Furthermore, lime is vital for neutralizing acidic solutions generated during the processing of aluminum ore, creating a safer and more environmentally responsible operational environment. This neutralization is critical in preventing the release of harmful acidic byproducts into the ecosystem.

How it Helps

- pH Adjustment – In the Bayer process, crushed bauxite is mixed with sodium hydroxide to dissolve the aluminum oxide present in the ore. Lime is often used to control the pH levels of this solution, optimizing conditions for aluminum extraction.

- Impurity Removal – Lime helps in the precipitation of impurities such as silica and other unwanted elements. These impurities are made insoluble and can then be easily separated from the aluminum-rich solution.

- Caustic Recovery – Lime is used in the recovery of caustic soda (sodium hydroxide) from the Bayer process. By adding lime, aluminum hydroxide precipitates out, and sodium hydroxide can be recovered and reused, making the process more efficient and sustainable.

- Environmental Responsibility – Lime supports responsible tailings management, reclamation, and environmental compliance, mitigating the environmental impact of mining operations.

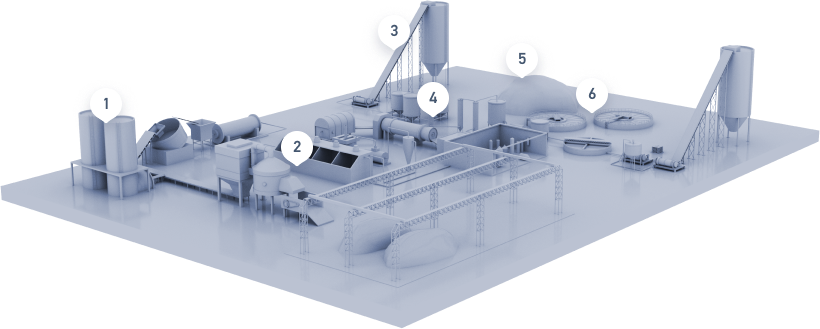

Lime Slaking Systems & Upgrades

Carmeuse Systems provides comprehensive equipment and storage solutions for aluminum production operations. We offer lime slaking systems, soda ash systems, dry material storage, and more. Our experienced engineers can design tailored solutions, including new lime handling systems, slakers, and retrofits or upgrades for existing equipment.

The Use of Lime in the Bayer Method

The Bayer process is the primary method used to extract aluminum from bauxite ore, a naturally occurring mineral rich in aluminum hydroxide. This method involves several steps. First, bauxite ore is finely ground and digested in a hot, concentrated solution of sodium hydroxide, also known as caustic soda. This caustic solution dissolves the aluminum from the bauxite, leaving impurities behind. Lime is then introduced to neutralize the excess caustic soda, which not only conserves caustic soda but also forms a solid residue called red mud. The red mud is subsequently separated from the liquid, and the remaining solution, containing dissolved aluminum, is further processed through precipitation and heating stages. This eventually leads to the formation of aluminum hydroxide, which, through calcination, is transformed into alumina (aluminum oxide). The alumina can then be smelted into aluminum metal. In the Bayer process, lime is instrumental in maintaining the correct pH balance and neutralizing the caustic soda, ultimately facilitating the efficient extraction of aluminum from bauxite ore.

Supplying Lime for Various Applications