Do you have a question about this application? Ask our specialists

Contact us

The Importance of Lithium Mining

Lithium mining is now an incredibly important industry due to the booming electric vehicle (EV) industry. As the world transitions towards cleaner and more sustainable transportation solutions, lithium-ion batteries have emerged as the dominant energy storage technology, powering EVs at the forefront of this transformation. The demand for lithium-ion batteries, driven by a global shift towards EVs, has spurred a dramatic surge in lithium mining activities. Lithium, a critical component of these batteries, has become the cornerstone of the green energy revolution, with mining operations expanding to meet the escalating needs of the automotive sector.

Lime is a crucial component necessary for lithium production resulting from lithium bearing ore or brines. Lime enables the balancing of pH, separation and purification from impurities, and the efficient extraction of lithium—a critical resource driving advancements in renewable energy technologies and the growing electric vehicle sector.

Our Role in Lithium Processing & Refining

What We Do

Lime plays a crucial role in the processing and refining of lithium, particularly in the transformation of lithium concentrate to lithium carbonate or hydroxide. In this intricate chemical process, lime is employed as a reagent to facilitate the conversion of lithium compounds. When converting lithium concentrate to lithium carbonate, lime is used in the precipitation step to facilitate the removal of impurities and unwanted metal ions, resulting in lithium carbonate, a more purified product. Similarly, if transitioning from lithium carbonate to lithium hydroxide, lime serves as an essential reagent during the precipitation and purification stages. The utilization of lime in lithium processing underscores its role as a key facilitator in ensuring the high-purity production of lithium compounds, critical for various applications in the rapidly expanding lithium-ion battery industry.

How it Helps

- Lime Precipitation – Lime is used to facilitate the precipitation of impurities and unwanted metal ions from lithium concentrate, the feed stock for lithium carbonate or hydroxide production.

- Impurity Removal – Lime helps in the removal of impurities, such as magnesium and calcium, which can interfere with the conversion process, ensuring high-purity lithium compounds.

- Lithium Conversion – In most conversions of lithium concentrate to lithium carbonate or hydroxide, lime is crucial for achieving the desired chemical composition and crystalline structure.

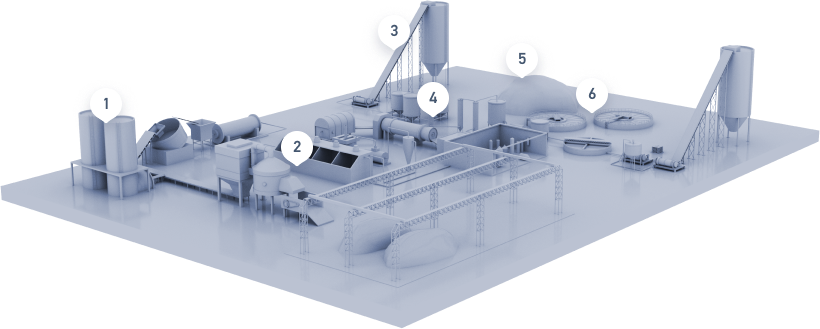

Lime Slaking Systems & Upgrades

Carmeuse Systems is able to provide equipment and storage options for lithium mining operations that includes slaking systems, soda ash systems, dry material storage.

Our expert engineers can design the right solution to keep your operation running smoothly, from new lime handling systems and slakers, to retrofits and upgrades for your existing equipment. For additional information related to our lime handling expertise, visit the website.

The Importance of Lithium Mining for a More Sustainable Future

Lithium mining is paramount to achieving sustainability goals through the widespread adoption of electric vehicles (EVs). As the world seeks to reduce carbon emissions and combat climate change, EVs are a crucial component of this effort, offering a cleaner and more sustainable mode of transportation. Lithium-ion batteries, powered by lithium extracted from mining operations, are the lifeblood of these vehicles, providing the energy storage capacity required for long-range, efficient, and environmentally friendly transportation. This shift not only significantly reduces greenhouse gas emissions but also decreases our reliance on fossil fuels. Ultimately, lithium mining plays a pivotal role in creating a more sustainable and eco-friendly transportation ecosystem, contributing to the achievement of vital sustainability goals by reducing air pollution, dependence on non-renewable energy sources, and the overall environmental impact of the automotive industry.

Supplying Lime for Various Applications