Do you have a question about this application? Ask our specialists

Contact us

The Importance of Nickel Mining

Nickel is a fundamental component of stainless steel, providing corrosion resistance and durability to this widely used material in construction, infrastructure, and consumer goods. It plays a pivotal role in the aerospace industry, where its exceptional heat resistance is crucial for aircraft engines and gas turbines.

In the realm of batteries, nickel is integral to the production of nickel-cadmium and nickel-metal hydride batteries, which power a variety of applications, from portable electronics to hybrid vehicles. The electric vehicle (EV) revolution further accentuates nickel's importance, as it is an essential component in lithium-ion batteries, the driving force behind the sustainable future of transportation. Additionally, nickel's applications extend to the chemical industry, where it serves as a catalyst in various processes. The enduring demand for nickel in sectors ranging from automotive to aerospace, energy storage, and construction underscores its pivotal role in advancing technology, infrastructure, and sustainability in the modern world.

Our Role in Nickel Mining

What We Do

Lime plays a pivotal role in the extraction and ore processing of nickel. In nickel extraction, lime is employed to optimize the pH levels in ore processing solutions, creating the ideal conditions for efficient nickel recovery. By adjusting the pH, lime enhances the dissolution and separation of nickel from the ore, leading to higher extraction yields and purity. Lime also plays a critical role in the removal of impurities, particularly iron and sulfur, by precipitating them, thereby improving the quality and purity of the extracted nickel. Lime is essential for neutralizing acidic solutions generated during the processing of nickel ore, contributing to a safer and more environmentally responsible operational environment. These functions are fundamental to ensuring that nickel mining operations produce high-quality nickel materials that are essential for a wide range of industrial applications, from stainless steel production to advanced technologies in aerospace and battery manufacturing.

How it Helps

- Ore Processing – Lime is used to enhance the efficiency of nickel extraction by optimizing the pH of processing solutions.

- Impurity Removal – Lime aids in the precipitation of impurities, making them insoluble and easy to remove, thereby enhancing the quality and purity of extracted nickel.

- Environmental Responsibility – Lime supports responsible tailings management, reclamation, and environmental compliance, mitigating the environmental impact of mining operations.

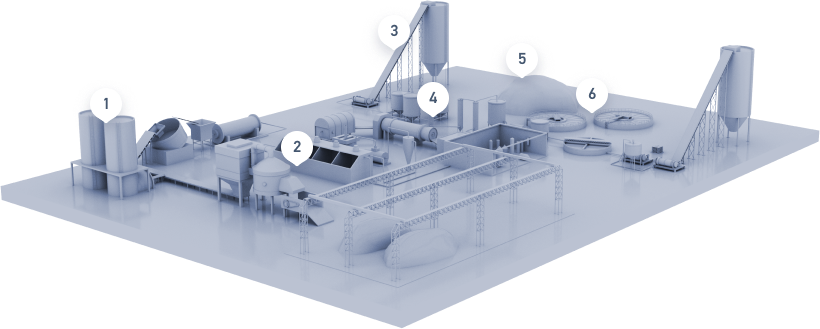

Lime Slaking Systems & Upgrades

Carmeuse Systems provides comprehensive equipment and storage solutions for aluminum production operations. We offer lime slaking systems, soda ash systems, dry material storage, and more. Our experienced engineers can design tailored solutions, including new lime handling systems, slakers, and retrofits or upgrades for existing equipment.

Supplying Lime for Various Applications