Do you have a question about this application? Ask our specialists

Contact us

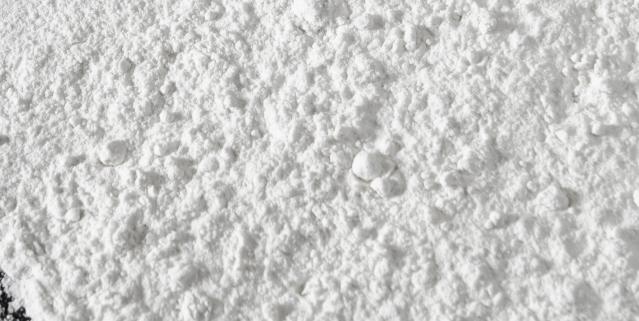

What Is Calcium Carbonate?

Calcium carbonate, which is also recognized as the chemical formula CaCO3, makes up almost five percent of the earth’s crust and is found all throughout the planet. CaCO3 is a combination of CaO (calcium oxide) and CO2 (carbon dioxide). Calcium carbonate’s most common natural forms are chalk, limestone, and marble. These forms of the material are produced by the sedimentation of prehistoric sea animal shells. Although chalk, limestone, and marble are indistinguishable in chemical terms, they are different from each other in many other ways. These differentiations include the material’s purity, whiteness, thickness and homogeneity (meaning how uniform its composition is). Calcium carbonate is a material that is as abundant as it is useful. With many different applications for the material throughout a variety of industries, it could be argued that calcium carbonate is one of the most useful and versatile materials in existence.

How Is Precipitated Calcium Carbonate (PCC) Made?

Precipitated Calcium Carbonate (PCC), also called PCC, is a synthetic calcium carbonate. PCC production requires consistent quicklime quality to produce a quality calcium carbonate. The precipitated calcium carbonate production process consists of decarbonating limestone, which separates the CaO (calcium oxide) and CO2 (carbon dioxide). Precipitated calcium carbonate is produced by slaking high-calcium quicklime to create a calcium hydroxide lime slurry, (Ca(OH)2), that is then combined with captured carbon dioxide (CO2). This process generates a very white and pure calcium carbonate with a controlled crystalline structure.

An even precipitation process allows good control of the crystallization and particle size of the PCC. Lime reactivity is key to achieving a finer particle size distribution and particle shape of PCC, as well as the stability of the process. Variations in quicklime quality can result in difficulties slaking and inconsistent particle size. This can lead to downtime, not meeting your customers’ needs, additional waste, and impact on your overall bottom line.

Our Role in the Production of Precipitated Calcium Carbonate

What We Do

Carmeuse and our affiliates support the needs of precipitated calcium carbonate manufacturers from End-2-End.

Carmeuse high calcium quicklime is an effective raw material for use in the production of precipitated calcium carbonate. Carmeuse can also provide lime handling equipment, including offloading, pneumatic conveying, and lime slaking systems to help maximize the efficiency of the production process. Our technical support experts can help resolve variations in your process to improve your Precipitated Calcium Carbonate consistency and keep your slaking operations running smoothly.

How it Helps

- High Calcium Content & Reactivity – Carmeuse high calcium quicklime is derived from select high calcium limestone deposits containing no more than 5% magnesium content. This high calcium content helps ensure high-performance and reactivity to achieve the proper particle size distribution in the slaking process required for PCC production.

- Consistent Quality – Carmeuse provides high calcium quicklime with low variation in quality to minimize adjustments in your processes and improve consistency of size and geometry of Precipitated Calcium Carbonate particles.

- Whiteness/Brightness – The high calcium oxide (CaO) content and low impurities (like iron oxide or manganese oxide) in the lime enable the production of a high-quality, white PCC.

Lime Slaking Systems & Upgrades

Over time, equipment used to produce precipitated calcium carbonate may need updated or replaced due to normal wear and tear or for the integration of new technologies. Carmeuse Systems supplies advanced equipment solutions for lime storage, handling, and slaking.

Our expert engineers can design the right solution to keep your PCC production running smoothly, from new lime handling systems and slakers, to retrofits and upgrades for your existing equipment. For additional information related to our lime handling expertise, visit the website.

Supplying Lime for Various Applications

Both precipitated calcium carbonate and ground calcium carbonate are the same in terms of their chemical composition both with the formula CaCO3 . However, ground calcium carbonate is produced by grinding limestone while precipitated calcium carbonate is changed through chemical changes including the calcination and slaking processes. As a result, the particle size distribution for PCC is finer and more consistent than can be achieved in GCC.

As mentioned above, the purposes of precipitated calcium carbonate vary between industries and this product can be used from paper manufacturing to the flooring industry. PCC can be found in sealants, adhesives, rubbers, inks, and more. In paper manufacture, both talc and PCC are used to whiten and increase the printability of the paper.