Do you have a question about this application? Ask our specialists

Contact us

What is Industrial Water Treatment?

Industrial water treatment involves removing or reducing the amount of chemicals, biological contamination, and undesirable water components found in industrial water. A water treatment system is used so that the water will become sufficiently clean for safe discharge into the environment.

Many different industries use water throughout the production process. For example, raw water is used in many cases in cooling towers, or for heating, cleaning, and rinsing. The waste stream that results from these processes must be handled appropriately to allow for re-use or to safely discharge to the environment. Many times, BOD is used to help determine how much treatment water needs. BOD (biochemical oxygen demand) is a measure of the amount of oxygen required to remove waste from water in the process of decomposition by using bacteria. Clean water needs a certain amount of oxygen and carbon dioxide to be present before it can be disposed of.

Our Role in Water Treatment

What We Do

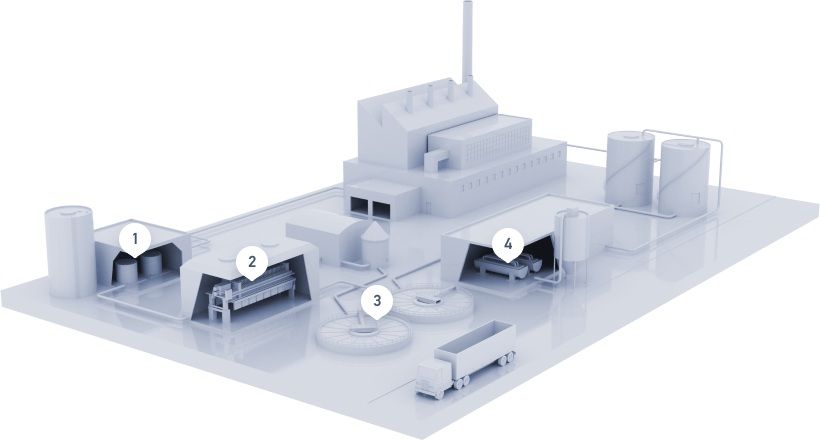

Carmeuse and our affiliates support industrial water treatment from End-2-End.

The use of lime throughout the industrial water treatment processes is crucial. Lime is used as a chemical treatment in an industrial water treatment system because of its ability to neutralize acidic waste and heavy metals, which improves water quality. Lime is considered a safer alternative to caustic soda, which is much more corrosive. Quicklime also has a stronger neutralizing capacity per dry ton and is more efficient at heavy metals precipitation when compared to caustic soda.

Carmeuse quicklime and related calcium-based products have been used for decades for industrial water treatment of water that contains a wide range of impurities. These lime-based industrial water treatment products meet EPA and DEP standards.

How it Helps

- pH Adjustment – Lime is used as a primary treatment in industrial water treatment systems because it can increase the pH level and neutralize the acidic properties of contaminated industrial wastewater.

- Heavy Metal Removal – Lime is also used as a flocculation aid to remove contaminants and heavy metals from industrial wastewater. These processes are used to ensure that the water can be repurposed for further use and that heavy metals do not contaminate natural water sources.

- Lime Softening – Hydrated lime can be used to remove hardness and precipitate solids out as a first-stage treatment for boiler feed water. This assists in the removal of dissolved and suspended solids for environmental compliance and aids in reuse.

Lime Slaking Systems & Upgrades

Over time, industrial water treatment equipment and its corresponding processes may need updated or replaced due to normal wear and tear or the evolution of new technologies. Carmeuse Systems supplies advanced equipment solutions for lime storage, handling, and slaking.

Our expert engineers can design the right solution to keep your industrial water treatment operation running smoothly, from new lime handling systems, to retrofits and upgrades for your existing equipment. For additional information related to our lime handling expertise, visit the website.

Supplying Lime for Various Applications

Meeting EPA and DEP Standards

Water produced from industrial processes rarely meets the requirements for release back into local waters without some level of industrial water treatment. These industrial wastewaters may be acidic and contain high dissolved metals content, organic contaminants, biological and chemical oxygen demand, dissolved mineral salts, and dissolved or suspended solids, among many other impurities. These impairments can create issues with meeting EPA and DEP regulations.

Carmeuse consistently provides lime-based products that have improved water quality for decades to reach DEP and EPA water standards. Products like high calcium quicklime, high calcium hydrated lime, and CALSAFE Lime Slurry, are routinely used in industrial water treatment.

Proper treatment of residual wastewater can utilize technologies like reverse osmosis, membrane filtration, or ultraviolet radiation.

Industrial wastewater can come from several sources, such as power plants, gas drilling facilities, food processing plants, steel production facilities, chemical manufacturing facilities, metal working facilities, nuclear plants, petroleum refiners, and textile mills, as well as many others.

Industrial wastewater treatment is necessary in order to produce clean water and reduce the amount of wastewater contaminants that are released into the surrounding environment. Treating industrial wastewater protects humans and the surrounding ecosystems by eliminating pollution.

According to the EPA’s website, The National Pollutant Discharge Elimination System (NPDES) permitting program has established limits on discharge and conditions for industrial and commercial sources. There are also limitations on the types of facilities and the activity that is allowed to generate wastewater.