The carbon footprint of the lime industry

The lime industry accounts for on average 1% of global industrial CO2 emissions. The vast majority of these emissions originate directly from the lime production in the kilns.

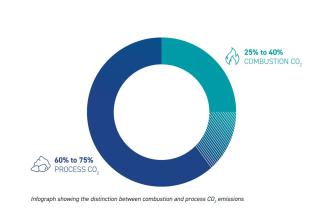

As the lime production process consists of decarbonizing limestone by heating it at temperatures above 900°C, there are two sources of direct CO2 emissions:

- Combustion CO2 emissions: These originate from burning fossil fuels to obtain the required heat. Depending on the kiln technology and the type of fuel, combustion CO2 emissions account for 25% to 40% of the total direct CO2 emissions.

- Process CO2 emissions: These result from the chemical reaction (calcination, the decomposition of limestone by releasing the embedded CO2) that occurs when limestone is heated. With the thermal decomposition, CO2 is emitted. This is what we call the process emissions, which represent 60% to 75% of the CO2 emissions.

Process emissions are unavoidable

These sources have different mitigation solutions. Combustion CO2 can be reduced by energy efficiency technology and fuel selection. Process emissions are unavoidable. The only way to deal with them is by capturing them and either utilizing them as a resource for other products or storing them permanently in minerals or deep underground rock formations. These are the so-called “Carbon Capture and Utilization or Storage” techniques, which will be touched upon in the section on disruptive technologies. The lime industry has relatively limited indirect CO2 emissions. Most indirect emissions originate from the purchase of electricity that is used for the preparation of limestone before the kilns, and the lime treatment after the kilns. It is important to address them also by producing our own renewable electricity, or by purchasing it on the market.

Our CO2 roadmap - going for zero carbon in 2050

Our global emissions of 10 million tons of CO2 per year account for approximately 0.025% of global CO2 emissions. We want to achieve this ambitious goal by prioritizing our initiatives. Our immediate focus is the mitigation of carbon emissions of our lime kilns as these represent more than 95% of our total CO2 emissions. Our roadmap is following the logical order:

- Avoiding CO2 in the first place. This is done through process optimization and by using the most efficient lime kilns. This has been our focus for a long time and we will continue this focus in the coming years.

- Secondly, we are ensuring the replacement of fossil fuels by non-fossil alternatives to reduce our combustion emissions.

- And as it is impossible to avoid process CO2 emissions, we need to deal with these emissions by developing disruptive technologies such as Carbon Capture and Utilization or Sequestration

Regional roads converging into one global roadmap…

As the regions where Carmeuse is active have a different history and regulatory framework, the roadmap has been broken down per region to take into account these differences, but with a clear view to converge into a global result in 2040 and ultimately in 2050 being fully carbon neutral.

Efficiency first

In 2022, all our production in the EU utilizes Best Available Kiln Technologies, ensuring the lowest energy consumption. Our latest achievement was the successful launch of new in-house developed kilns (via TECForLime) at our Kosice site in Slovakia.

In North America, the priority focus is to increase the efficiency of our existing rotary kilns. These kilns generally use more fuel and so emit more CO2 than vertical kilns. Measures, such as adaptation of processes, or expert systems, can improve kiln efficiency. In the long run, we aim to convert or replace these kilns with the Best Available Kiln Technologies, similar to the introduction of vertical PFR kilns in Winchester in 2016.

Beyond the Americas and Europe, we operate everywhere with the Best Available Technology kilns. We just fired up our brand-new lime kiln in Senegal for instance, we are already working with state-of-the-art kilns in Oman and we’ve invested in a solar farm at the Chong Sarika site in Thailand.

Switching to low-carbon fuels represents another opportunity to reduce CO2 emissions. We’ve been actively pursuing this idea through Fuel Flexibility projects based on availability and fuel cost at each site. We’ve paved the way for a 26% reduction of combustion CO2 emissions in 2030 versus our 2019 asset base. We’ve investigated and developed multiple asset modernization scenarios for that purpose, each with different technical (according to the suitability of the limestone), commercial (market acceptance) and financial impacts. We are also exploring carbon capture and storage opportunities close to our facilities and are partnering with a number of operators to develop these types of projects to be implemented in the coming years.

In the rest of the world, we are working on two new solar farms to increase our renewable electricity portfolio. All electricity is for our own consumption.

Disruptive solutions will be essential to achieve our ambitions

Disruptive technologies are the main focus/passion of our TECforLime colleagues who are working hard to prepare the CO2 mitigation solutions. They’re studying and developing different Carbon Capture techniques, with the objective to create sufficiently concentrated CO2 in order to capture it in the most efficient way. Typically, CO2 exiting our kiln is diluted, so CO2 only forms 20% of the fumes that exit. The challenge is to bring this concentration as close as possible to 100 %. This implies the development of new technical solutions for our different kilns by means of capturing CO2 at the exit of the kiln, or creating a new type of kiln that facilitates carbon capture. We have obtained a permit at one of our sites in Belgium for our “Butterfly” project in which we collaborate with several other partners. This pilot installation will target the capturing and concentration of CO2 directly in the lime manufacturing process.

Capturing CO2 is not enough

Once CO2 has been sufficiently concentrated and consequently captured, the CO2 needs to be handled further to avoid it being released back into the atmosphere. There are two ways to deal with this: either the CO2 is used as a resource in other products, or it is permanently stored/sequestrated, typically in underground reservoirs, such as depleted gas fields.

Carbon Capture and Utilization

This is the technique whereby the captured CO2 is utilized, either as feedstock to create a new type of fuel (e-fuels, like e-methane or e-kerosene) or to be embedded permanently in other materials (polymers for example). We are participating in a number of projects related to this technique.

Carbon Capture and Storage

This technique captures CO2 and permanently stores it in geological formations. CCS is an essential part of the road to carbon neutrality. The number of CCS projects is growing exponentially but accessing these requires overcoming enormous logistical challenges. Apart from the challenge to capture the CO2 in a sufficiently concentrated form, the CO2 also needs to be transported to sequestration sites. And it needs to be secured that no CO2 can escape later from these fields.

Reducing the carbon footprint of our customers

This is the last and important piece of our CO2 roadmap: in optimizing their processes and the use of our products. This optimization helps to reduce their CO2 emissions.

The same goes for the development of new products: products like our soil stabilization products, or the filler blend that can replace up to 20% of cement in concrete, have an important impact on the carbon footprint of our customers.

A rather unknown fact is that the use of lime in various applications leads to a spontaneous absorption of CO2 from the ambient air. A study by Politecnico di Milano, University of Milan, Italy, commissioned by the European Lime Association, has shown that on average 33% of the CO2 process emissions emitted during the production process of lime, is re-absorbed in the use phase during the first 12 months.

To give some examples: when lime is used in flue gas treatment, to treat drinking water or in the production of pulp and paper, carbonation occurs instantaneously and fully. Meaning that CO2 is being absorbed instantly from the ambient air. The amount of absorbed CO2 equals the process CO2 emitted during its manufacturing.

In the iron and steel industry, carbonation occurs during the open-air storage of slags, typically lasting between 3 and 6 months.

Lime used in various construction materials, such as mortars, will carbonate gradually during the lifetime of the building.

By using special techniques, there is a potential to increase this absorption even further.

State of Play 2023

The Sustainability State of Play gives us a clear picture of where we are today, but also where and how we can do better.

We’ll continue to use our collective energy to achieve our purpose and to shape a sustainable future for our company and communities.