Do you have a question about this application? Ask our specialists

Contact us

The Process of Fiberglass Production

The process of producing fiberglass involves the transformation of raw materials into thin, strong fibers used in various industries. It typically begins with the selection of raw materials, primarily silica sand, which is heated to high temperatures to create molten glass. This molten glass is then extruded through fine openings to form continuous filaments, which are rapidly cooled and solidified to create glass fibers. These fibers can be further processed into various forms, such as yarn or mats, depending on the intended application. Fiberglass is renowned for its exceptional strength, insulation properties, and versatility, making it a valuable material in applications ranging from construction and automotive industries to aerospace and consumer goods.

It is commonly used in the construction sector for reinforcing concrete and as an insulating material, providing strength and thermal efficiency. In the automotive industry, fiberglass is utilized for lightweight components that enhance fuel efficiency without compromising safety. It finds extensive use in aerospace and marine applications due to its exceptional strength-to-weight ratio, making it ideal for aircraft components and boat hulls. In addition, fiberglass is a popular choice for manufacturing composite materials in the production of sporting goods, from surfboards and tennis rackets to fishing rods. Its electrical insulating properties also make it indispensable in the electrical and electronics industry. Overall, fiberglass's strength, durability, and versatility have made it an integral material in modern manufacturing and construction, enabling a wide array of innovative and high-performance products.

Our Role in Fiberglass Production

What We Do

Carmeuse is a producer of high-quality dolomitic lime which is a critical component in the production of fiberglass. Dolomitic lime is used primarily to facilitate the melting of the raw materials. It acts as a flux, reducing the melting point of the glass batch, thus lowering the energy consumption required in the furnace. By promoting efficient and uniform melting, dolomitic lime ensures the quality and consistency of the glass fibers produced. Additionally, it contributes to the stable viscosity of the molten glass, aiding in the drawing and formation of fine and uniform fibers. In essence, dolomitic lime is an essential enabler in the production of high-performance fiberglass, contributing to the cost-effectiveness and quality of the final product.

How it Helps

- Flux in Glass Production – Lime is a key component in the glass batch used to create the molten glass from which fiberglass is drawn. It acts as a flux, reducing the melting point of the glass, making the process more energy-efficient.

- Stabilizes Viscosity – Lime contributes to the stable viscosity of the molten glass, allowing for the formation of uniform and fine glass fibers during the drawing process.

- Reduces Energy Consumption – By lowering the melting point of the glass batch, lime helps reduce the energy consumption required in the furnace, enhancing the cost-effectiveness of fiberglass production.

- Strengthens Glass Fibers – Lime's role in stabilizing the glass composition and facilitating efficient melting ensures that the resulting glass fibers are strong and of high quality, making them suitable for a wide range of applications.

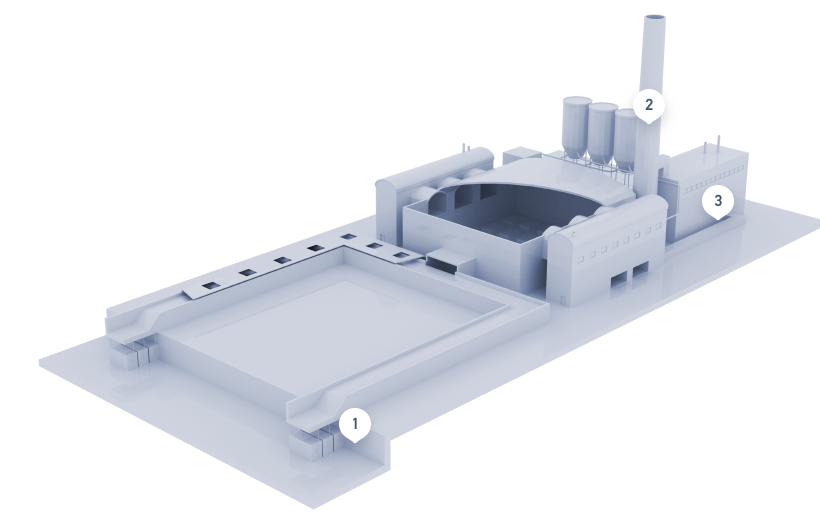

Lime or Soda Ash Storage & Conveying Systems

High volume production places high demand on your equipment. Carmeuse Systems provides comprehensive equipment and storage solutions for storage and pneumatic transfer of your bulk materials. Our experienced engineers can design tailored solutions, including new lime handling systems and retrofits or upgrades for existing equipment.

Supplying Lime for Various Applications