Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features

- Autoclaved Aerated Concrete (AAC) is produced by mixing quicklime with cement, gypsum, sand, water, and a limited amount of aluminium powder. It results in a slurry that rises and sets to form lightweight and honeycomb-structured white blocks.

- AAC is considered one of the most sustainable building bricks, responding to the fast-growing need for affordable housing.

Benefits

- Resource efficiency

- Lightweight

- Ease of use

- Excellent thermal insulation properties

- Fire resistance

- Reduced carbon footprint

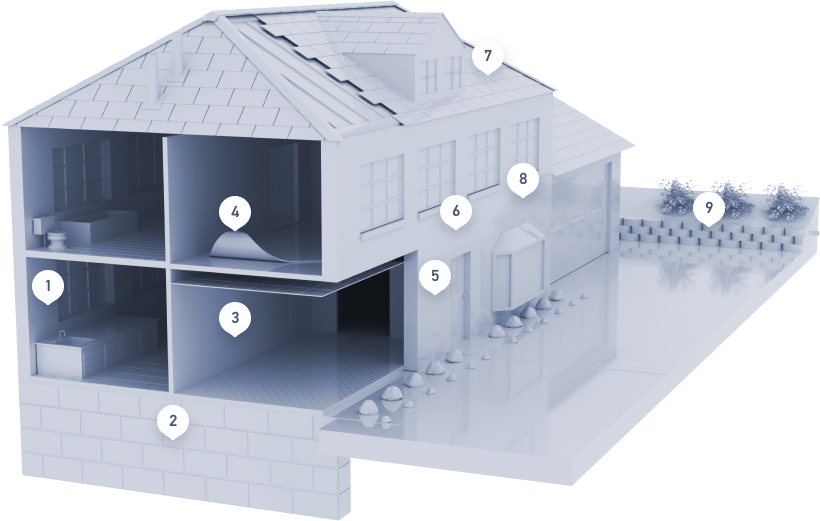

Dedicated solutions for your specific needs

AAC is recognized as a sustainable building technique and is very resource efficient, as densities can be achieved even below 250 kg/m³. Quicklime, which offers reactivity and fineness, is a key element in the casting process of AAC products. These include autoclaved aerated concrete blocks, wall panels, floor panels, roof panels, cladding (facade) panels and lintels.