Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features

- Desulfurization – reduction of sulphur concentrations as low as 0.002%.

- Micro cleanliness – removal of undesirable non-metallic elements.

- Lime/dolime based products are designed for slag conditioning, production of clean steel, and steel desulphurization.

- Products provide additional thermal insulation of the ladle during casting.

- Lime removes macro impurities in primary metallurgical processes, enabling the final refining stage. At this point, alloys are added to finish the production of steel and prepare it for casting and shaping.

- Our lime meets the chemical and physical characteristics required by this final refining stage. Additives must be chosen and added carefully in order to remove indigenous inclusions and keep any external impurities out.

Benefits

- Efficient desulphurization and utilization of alloying elements.

- Formation of slag layer that protects ladle refractory from arc damage (LF), concentrates and transfer heat to the liquid steel, trap inclusions and metal oxides.

- Provide a means for deep desulphurization.

- Improved control of slag viscosity.

- Prevents reoxidation of the steel.

- Act as a buffer for downstream equipment and process.

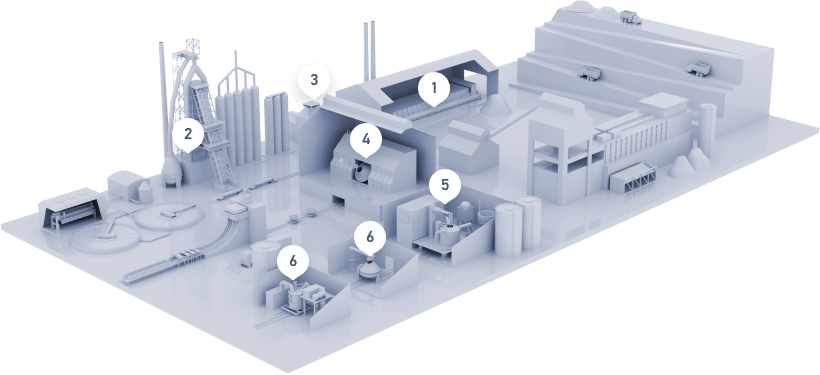

Dedicated solutions for your specific needs

Our Role

At Carmeuse, we understand that each steel manufacturer's requirements are unique. That's why we emphasize a cooperative approach and work hand-in-hand with our customers. Through this partnership, we delve into the intricacies of your current slag manufacturing processes to identify areas that can be improved and to offer lime-based products and tailored synthetic slag design to further improve efficiency thus increasing your profitability and sustainability.