Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features

- Calcium and magnesium from lime/dolime and limestone/dolostone are essential components in sinter or pellets to reach proper basicity index and balance acidic components like silica.

- Efficiency of the agglomeration of the iron ore fines and optimizing water addition.

- The quality, granulometry, quantity, and method of lime addition to the agglomeration process are critical to influence sintering or pellets drying and firing.

- Lime addition into the mix indicates a positive effect on the heat content in the sinter bed leading to shortening sintering time and possible fuel savings.

Benefits

- Lime, as an intensifier of the process, leads to improved agglomeration and permeability of the sinter mix.

- Pelletization with lime improves the sizing.

- Lime has positive effects on the productivity of the sintering or pellets firing process leading to fuel savings and CO2 emissions.

- Adding good quality fluxed sinter feed to the blast furnace increases softening and melting temperature and it improves reduction. Sinter strength plays an important role in deciding the PCI rate in blast furnaces.

- Optimal basicity index pellets allow early-stage impurities removal and better heat and mass transfer during reduction.

Dedicated solutions for your specific needs

Our Role

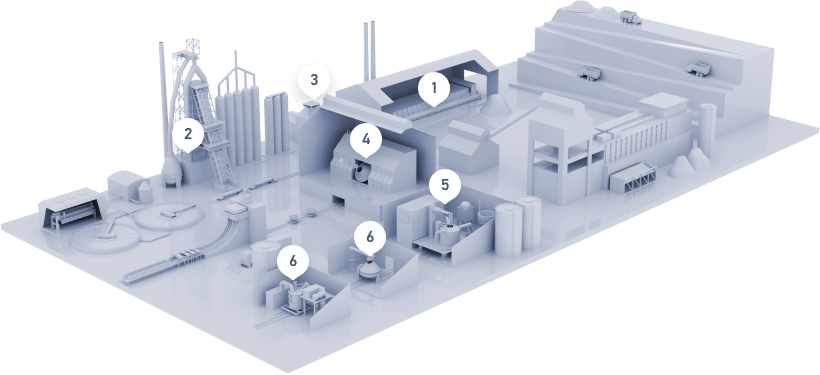

Sintering facilitates feed of iron ore fines in blast furnace, blended with fluxes and coking coal / coke. The depletion of iron ore quality poses new challenges to steel makers. There is a need to find alternate solutions maintaining optimal composition and metallurgical properties of the sinter to enable the production of high-quality hot metal and finally steel.

We at Carmeuse developed expertise in offering customized solutions based on numerous sets of experiments related to the sintering process. Sintering of iron ore has always been a potential process to improve emissions and reduce costs. Carmeuse research on lime characteristics for sinter enabled to offer engineered products and customized services for improving quality of the sinter, keeping focus on cost savings, and reducing environmental impact of the sintering process.

Quality limestone or dolostone is also used in pelletization to adjust the basicity and to contribute to pellets hardness. Lime can also be used and allows to limit the use of bentonite which contributes negatively on the basicity.