Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features of Hydrated Lime

- Building lime has been used in construction for thousands of years as a binder. The Romans used air lime in combination with natural and artificial pozzolans.

- Mortar formulations have developed over time, and in the last century it was common practice to combine hydrate and cement. In this way, lime has been used extensively as a component of masonry mortars, plasters and renders to provide the mason with a better mortar workability in the fresh state.

- These benefits essentially relate to the development of better water retention and air entrainment. In addition, because of the reaction with carbon dioxide from the air, lime hardens and contributes to the overall strength of the mortar, while also acting as a carbon sponge.

Features of Milled Limestone

- Limestone fillers with a high calcium carbonate content form the fine-grained skeleton of any mortar, plaster or render.

Benefits of Hydrated Lime

Fresh mortars:

- Workability

- Water retention

- Air content

Hardened mortars:

- Mechanical behavior of cement-lime mortars

- Thermal and moisture movement in masonry

- Resistance to rain penetration

- Resistance to salt crystallization and chemical attack

- Frost resistance

- Carbon sequestration

- Color consistency

Benefits of Milled Limestone

Hardened mortars:

- Correction for coarse sands, missing fines

- Consistency in specific surface and water absorption

- Color consistency

Dedicated solutions for your specific needs

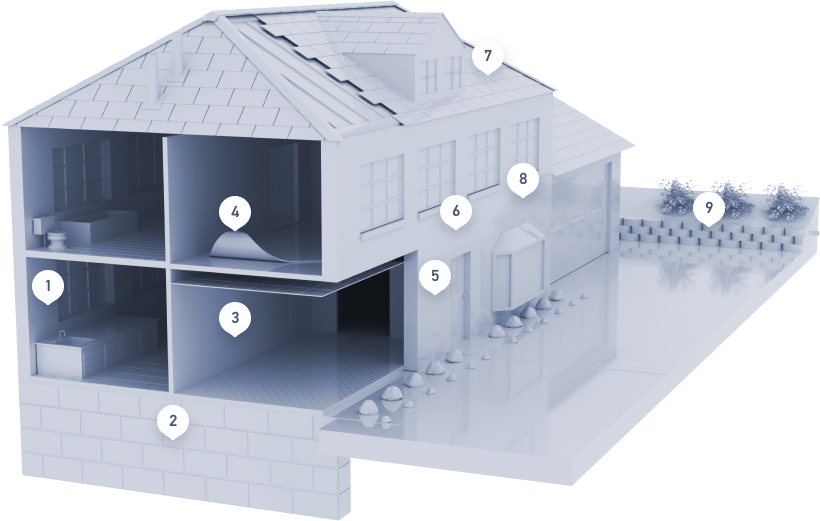

Owners involved in construction or renovation aim to use reliable solutions and materials. These can positively contribute to a building’s functional, aesthetic and sustainability requirements, in addition to the well-being of people who live and work inside the building.

Designers, architects, and engineers need a reliable end-product that meets owners’ needs. They must combine the short-term requirements of the contractor, who needs to work quickly and economically, and the long-term requirements of the building’s owner, who needs a durable, attractive, and trouble-free construction.

Craftsmen look for workable and consistent products that enable easy handling. The joints and beds of masonry mortar must be readily and completely filled, while the units must be placed, and their position adjusted quickly and easily. Mortars, renders and plasters must have properties that help a craftsman to work smoothly, quickly, and economically with minimum waste and consistent work quality.

Our range of SuperCalco® (Europe), Enduria® (only in Romania) and Barkisan® (only in Turkey) products offer hydrated lime solutions for your masonry units, in new and renovation construction. This range offers the following benefits for all stakeholders in this process:

Workability:

- With SuperCalco®, a fine particle binding agent with a very large surface area, the mix can hold a greater quantity of water. It also enhances the fluidity of the mix, thus improving its stability.

Work quality:

- The smoother and more workable consistency of SuperCalco® mortars – plus the retention of water in the mortar immediately after application – help to promote good workmanship. This enables the complete filling of beds, easier perpending, and smooth finishing of the plaster. The final result is high-quality joint finishing and tooling.

Cost savings:

- SuperCalco® mortars can be more economical to use. Thanks to a combination of workability, water retention and easier use – with more consistent and accurate joint filling and better adhesion – there is typically less waste. Better quality workmanship will also reduce the likelihood of rework or remedial measures.

Bond strength:

- SuperCalco® mortars have excellent adhesion and bonding properties, thanks to their high degree of workability, stickiness, and water retention. They are also able to create continuous bonds with brick surfaces and can completely fill the spaces within them.

Water leakage:

- Water penetration into masonry and buildings is essentially a failure of the building system to prevent moisture ingress. Water is the driving force behind their deterioration and can fundamentally affect the performance and durability of many components in buildings. Masonry walls constructed with SuperCalco® mortars have good resistance to water leakage.

Durability:

- Until the late 20th century, almost all masonry buildings used lime-based mortars. Their durability and long-term performance are highlighted by the myriad of historic buildings found in our towns and cities.

High flexural strength combined with suitable compressive strength:

- Cracking is commonly caused by inappropriate mortar strength relative to the units being mortared together. Softer lime-based mortars offer greater elasticity and help to accommodate minor movements and volume changes, thus reducing the need for movement joints. SuperCalco® mortars are more flexible and can absorb a high degree of deformation before breakage.

Environmental performance:

- At the end of a building’s life, SuperCalco® mortars allow building materials to be more easily re-used, contributing to resource efficiency.

The numerous historic buildings in our cities show that lime-based mortars and finishes effectively contribute to long-lasting performance.

Lime-based mortars are generally softer than bricks. This makes the mortar easy to remove without causing damage, since bricks originally laid with lime-based mortars can be cleaned and re-used in new constructions.