Do you have a question about this application? Ask our specialists

Contact us

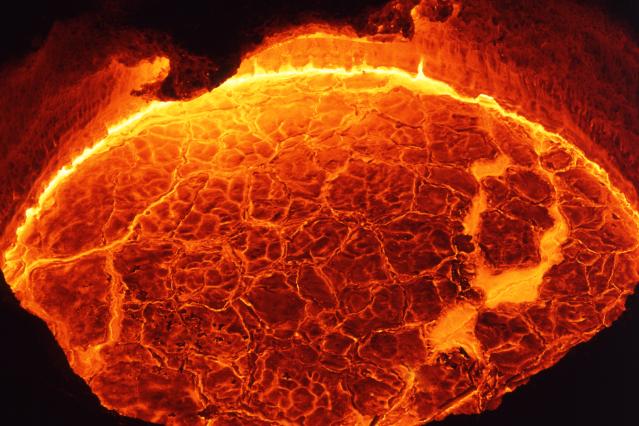

LRF PROCESSES

Refining in the Ladle Refining Furnace (LRF) is the last but the most important stage of the steel melting process. This stage gives a final chance to refine the steel and adjust both its chemical composition and temperature. Slag composition is of great importance and there should be no compromise on the selection of fluxes, ensuring the highest quality possible. Carmeuse lime products or blends are efficiently contributing to steel refining by removing remaining impurities like sulphur and protecting refractories.

ARGON OXYGEN DECARBURIZATION

Argon Oxygen Decarburization (AOD) process is used in stainless steelmaking containing oxidizable elements such as chromium. Carmeuse high quality lime with low C content is required for achieving optimum deoxidation and desulphurization without interfering decarburization.